The REV Inserts

More than keyways and slots – cut square, hexagon and pentagon holes, involute teeth, PTOs and more

The REV Broaching Insert and Tool can cut in either through or blind holes with or without a relief groove or a .2mm x 45° chamfer. Ideal for both single and timed or multiple cuts. Inserts and tools are available to cut, square, hexagonal, pentagonal holes and involute teeth, as well as keyway slots, PTOs and special shapes.

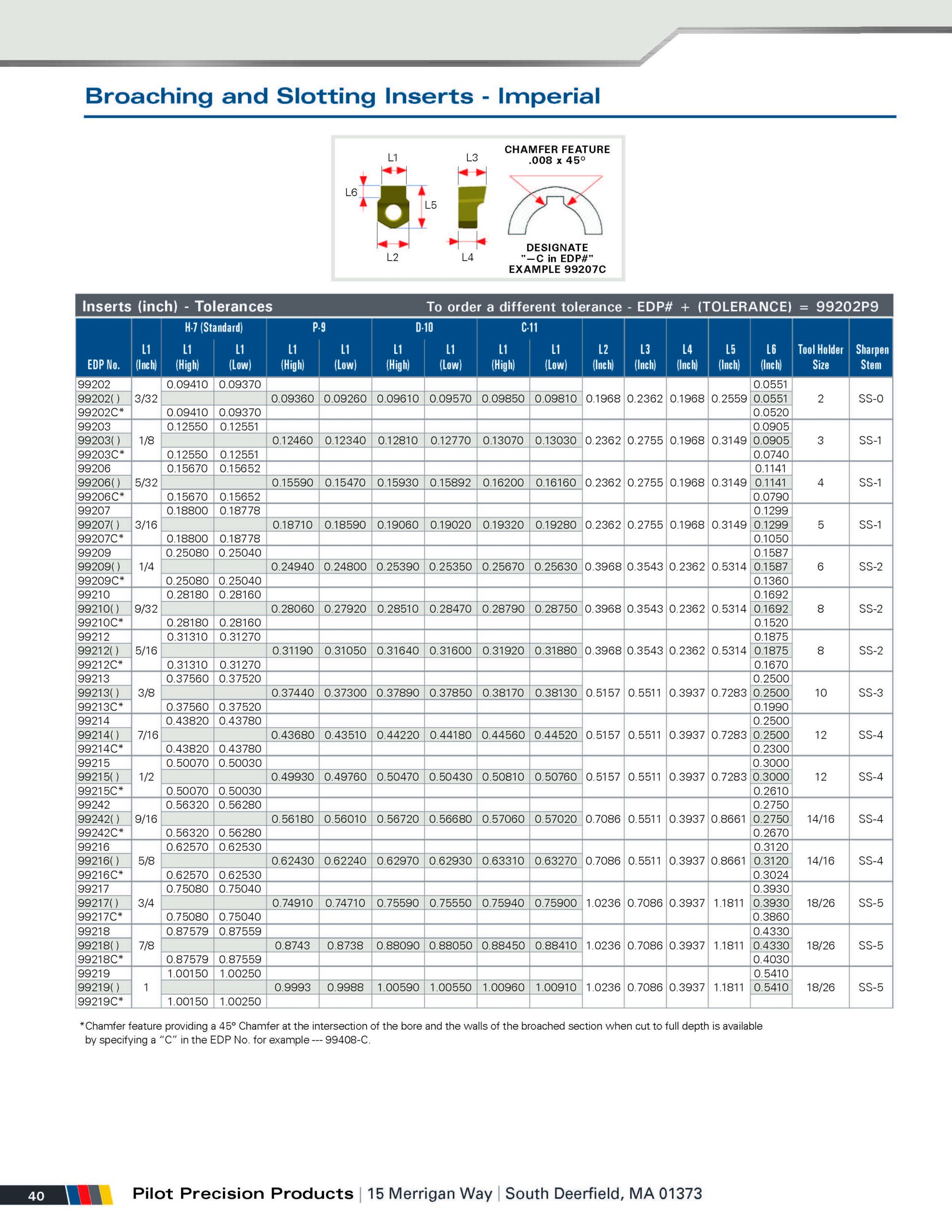

The broaching and slotting inserts are made with a sintered alloy which, following heat treatment, reaches a hardness of 72 HRC. This material gives the REV broaching inserts high toughness, and can accordingly withstand strong pressures, with the subsequent possibility of using increments of up to 0.2 mm on steel and 0.3 mm on cast iron without breakage during processing. These increments would not be possible if the inserts were manufactured with a different material, like the majority currently available on the market. The inserts are also subject to a surface treatment, TiN coating, with anti-wear and seize properties. The inserts are re-sharpened by tapering their sides. This process eliminates any gouges that would prevent the insert from cutting perpendicular to the reference axis of the workpiece during the broaching phase. The protruding shape of the inserts makes it possible to re-sharpen them numerous times. All of these characteristics make REV inserts extraordinarily long-lasting. The inserts are available for immediate delivery in 27 sizes (considering millimeter and inch-based measurements), and 4 tolerance classes for each size (C11, D10, H7 and P9). Inserts measured in millimeters identified by the code ending with “SM” provide a 0.2mm x 45° chamfering on the intersection point between the hole and the walls of the broached slot, leaving the hole burr-free. This type of chamfering can only be carried out on UNI keys. We also produce special inserts and tools, based on specific customer demands, and provide a quick turn-around of inquiries and orders. Inserts may be re-sharpened using a re-sharpening rod. Re-sharpening can extend the life of the tool reducing the cost per cut. The re-sharpening rod has a comfortable grip and ensures that the insert protrudes from the rod, making the operation easier to perform.