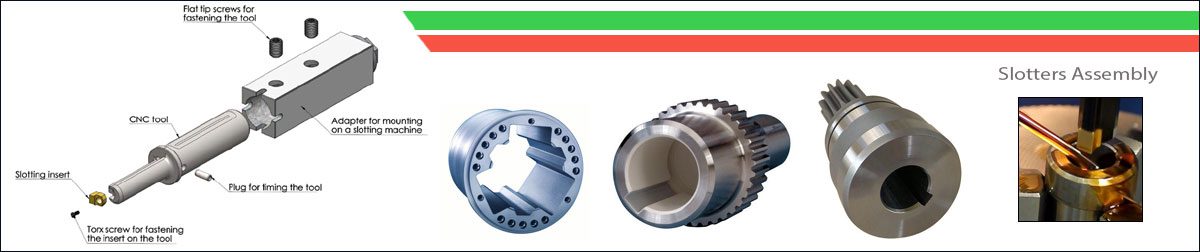

The REV System for Slotting and Shaping Machines

Increased versatility and rigidity

The REV Broaching Tool can be used, in addition to machining centers and CNC lathes, also on traditional machines such as slotting and shaping machines, offering great sturdiness and versatile use, unlike tools commonly used on these machines. REV system offers a square or prismatic adapter to clamp the tool to a slotting and shaping machine. The REV adapter makes it possible to process the hole in four positions at 90° angles to each other. It is made with 39NiCrMO3 which, through tempering, reaches a hardness of 58/60 HRC and is then ground. The toughness and rigidity of this material make it possible to achieve processing with an excellent surface finish. The adapter is equipped with two threaded holes where the two M12x8 flat point grub screws are inserted and used to clamp the tool to the inside of the adapter. The tool’s timing pin guarantees a perfect position of the tool in relation to the work axis. The adapters are available to accommodate either tools with 25mm or 32mm shanks. REV offers the solution of clamping the tool on by a square adapter, however, this is only one of the many ways it is possible to set up the REV Broaching Tool on slotting and shaping machines. REV technicians are in fact able to adapt the tool to all slotting and shaping machines on the market by modifying the part designed for clamping to the machine. We also produce special inserts and tools, based on specific customer demands, and provide a quick turn-around of inquiries and orders.

1. Place the insert in the tool housing and clamp in on by tightening the Torx screw with the screwdriver;

2. Insert the tool inside the square adapter and lock it in place using the flat point grub screws;

3. Attach the square adapter to the slotting or shaping machine.

Partnering with Industrial Distribution to deliver the service and support you deserve.